Condition Monitoring

In FGE we do believe in reliability and its very important rule in the integrity of rotating equipment maintenance. That’s why we initiated a highly professional, trained and equipped condition monitoring team that aims to achieve our clients’ satisfaction through applying predictive and proactive maintenance programs, Which includes:

• Vibration Analysis, fault detection and diagnosis of rotating equipment.

• Commissioning of newly installed or recently maintained equipment.

• Vibration based overhauling.

• Balancing on site for rotating equipment.

• Alignment of all types of rotating equipment.

• Lubrication using ultrasound techniques.

• Run up & Cost down tests.

• Oil Analysis.

• Thermography services.

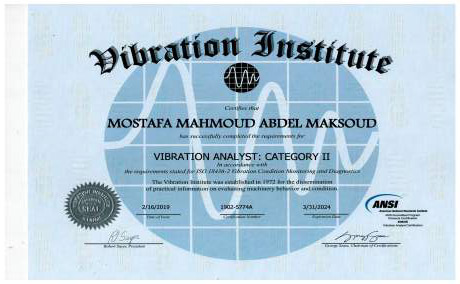

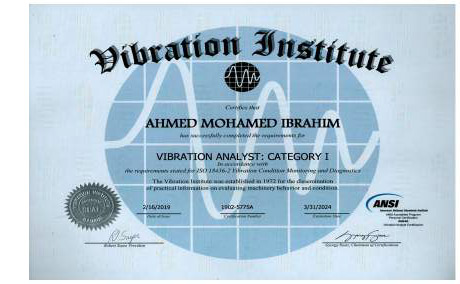

FGE has a highly professional and trained staff for the condition monitoring services who are: Internationally certified from American Vibration (7 Certified Engineers)Institute as CAT II vibration analysts Trained on all types of laser alignment Trained on ultra sound techniques

OneProd Vibration Analyzer Falcon APT 2039

• Complete set of vibration analysis system

• Data collector

• Three axis wireless Sensors

• Balancing Module

• Multiply channels

• Built in stroboscope, pyrometer, camera and audio comment recorder

This device along with all its features and modules enables us to conduct many services to our clients such as:

1. Vibration analysis.

2. On-site Balancing

Vibration analysis is considered the corner stone of successful reliability centered

maintenance program, also vibration has been used to save industry millions of dollars in machine downtime as it has traditionally been associated with trouble in machines-wear, malfunction, noise, and structural damage

So, FGE is offering routine based vibration analysis to be able to

identify any fault and enable you to plan to take maintenance action

before a failure occurs.

maintenance program, also vibration has been used to save industry millions of dollars in machine downtime as it has traditionally been associated with trouble in machines-wear, malfunction, noise, and structural damage

So, FGE is offering routine based vibration analysis to be able to

identify any fault and enable you to plan to take maintenance action

before a failure occurs.

maintenance program, also vibration has been used to save industry millions of dollars in machine downtime as it has traditionally been associated with trouble in machines-wear, malfunction, noise, and structural damage

So, FGE is offering routine based vibration analysis to be able to

identify any fault and enable you to plan to take maintenance action

before a failure occurs.

maintenance program, also vibration has been used to save industry millions of dollars in machine downtime as it has traditionally been associated with trouble in machines-wear, malfunction, noise, and structural damage

So, FGE is offering routine based vibration analysis to be able to

identify any fault and enable you to plan to take maintenance action

before a failure occurs.ON-SITE BALANCING

Balancing of rotating machinery becomes an essential and vital demand in order to ensure reliable operation of newly designed rotating machinery, So FGE put a great concern in the balancing service regarding the industries and market demands Our company efficiently performs different types of balancing on site for most types of equipment if applicable:

• Air cooler fans

• Centrifugal fans and blowers

• Centrifugal pumps

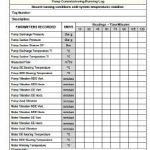

VIBRATION TESTS AND MONITORING

During our achievement in all the commissioning activities we performed, the final judgment on the equipment status was to monitor the vibration and temperature on the equipment bearings

BVT 30 Vibrometer

• Overall vibration Collector

• Temperature Gun

FGE Tested more than 2000 rotating equipment, recording vibration and temperature values in professional forms to be used as the official form for the equipment release and to be documented by clients

LASER ALIGNMENT

Recent statistics have proved that almost 50% of reported cases of failure in different component of machinery trains are originally caused by misalignment.

FGE engineers and technicians are very precise in all types of laser alignment.

We have great experience in laser alignment as we faced almost all alignment and soft foot problems.

During the commissioning phases in ZOHR field, FGE successfully aligned more than 1300 rotating

equipment such as; pumps, compressors, fans, blowers and turbines.

Easy Laser XT 440

• Complete set of laser alignment system

• Horizontal shaft alignment

• Vertical shaft alignment

• Machine train alignment

• Soft foot

• Pulleys alignment

• Cold/Hot alignment

ULTRASOUND LUBRICATION

Poor lubrication practices are a leading cause of bearing failure. LUBE Checker is an ultrasound solution focused on optimizing grease replenishment. It is the perfect companion fo performing lubrication on condition based intervals.

Ultrasound LUBE Checker

This intuitive device ensures bearings receive the right amount of grease at intervals dictated by condition, not run time. LUBE Checker uses the LUBE Sense, a robust, repeatable sensor built to withstand harsh conditions